In today's rapidly evolving industrial landscape, efficient airflow management is crucial for maintaining optimal working conditions and ensuring equipment longevity. Industrial axial fans have emerged as a cornerstone technology in addressing these challenges, particularly in large-scale facilities where air movement is critical. This comprehensive guide explores the significant impact of industrial axial fans on airflow improvement and their essential role in various industrial applications.

Understanding Industrial Axial Fans

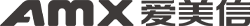

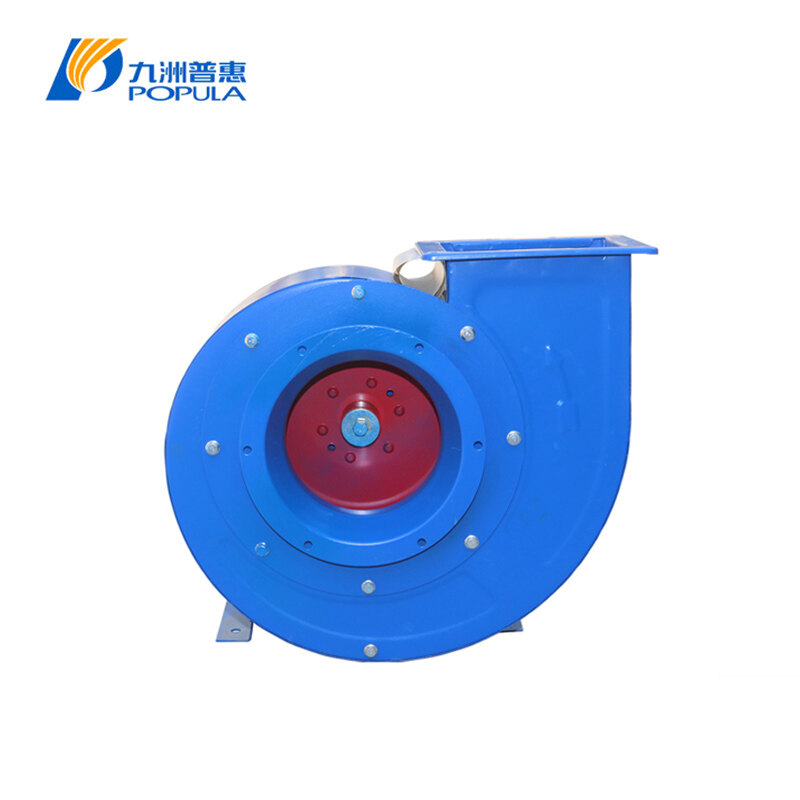

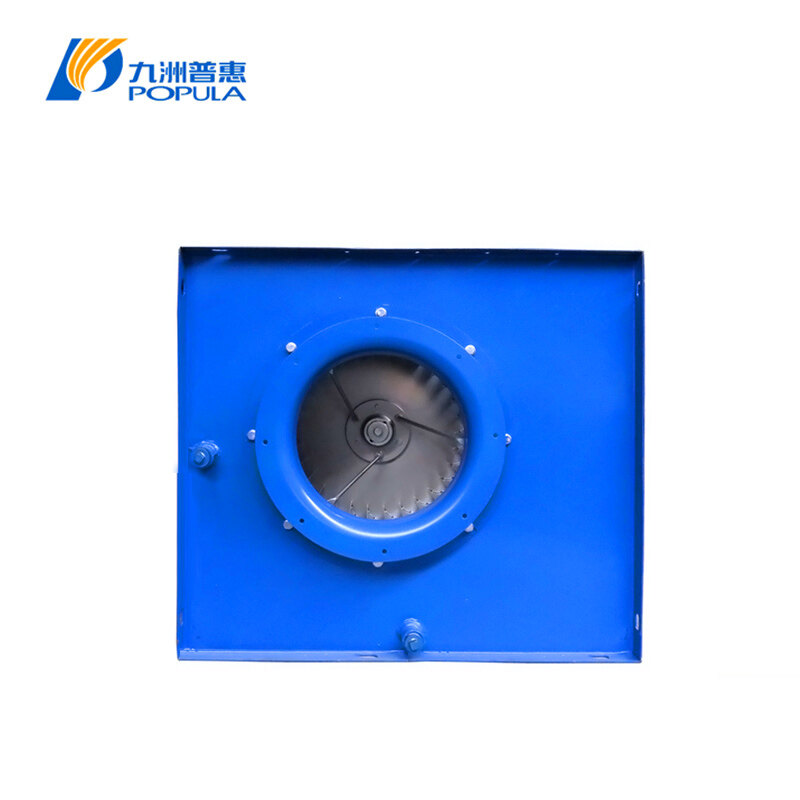

Industrial axial fans are powerful air-moving devices designed to handle high volumes of air at relatively low pressures. These fans operate on a simple yet effective principle: air enters the fan parallel to the rotating shaft and exits in the same direction. This design allows for efficient air movement, making industrial axial fans ideal for applications requiring substantial airflow.

Key Features of Industrial Axial Fans

High Volume Capacity: Capable of moving large quantities of air efficiently

Versatile Design: Suitable for various industrial environments

Energy Efficiency: Optimized for lower power consumption compared to other fan types

Durability: Built to withstand harsh industrial conditions

Customizable Options: Available in different sizes and configurations to meet specific needs

Applications in Large-Scale Facilities

Industrial axial fans play a vital role in numerous large-scale facilities, significantly improving airflow and overall operational efficiency. Some key applications include:

Manufacturing Plants

In manufacturing environments, industrial axial fans help maintain air quality by removing heat, fumes, and particulates. This not only ensures a safer working environment but also helps prevent equipment overheating, leading to increased productivity and reduced downtime.

Warehouses and Distribution Centers

Large warehouses benefit from the high-volume airflow provided by industrial axial fans. These fans help regulate temperature, reduce humidity, and prevent the buildup of stagnant air, creating a more comfortable and efficient working environment for staff and preserving stored goods.

Power Generation Facilities

Industrial axial fans are crucial in power plants for cooling generators and other heat-producing equipment. Their ability to move large volumes of air efficiently makes them indispensable in maintaining optimal operating temperatures and preventing equipment failure.

Agricultural Facilities

In large-scale agricultural settings such as greenhouses or livestock facilities, industrial axial fans play a critical role in temperature regulation, humidity control, and air circulation. This helps maintain ideal growing conditions for crops or a healthy environment for animals.

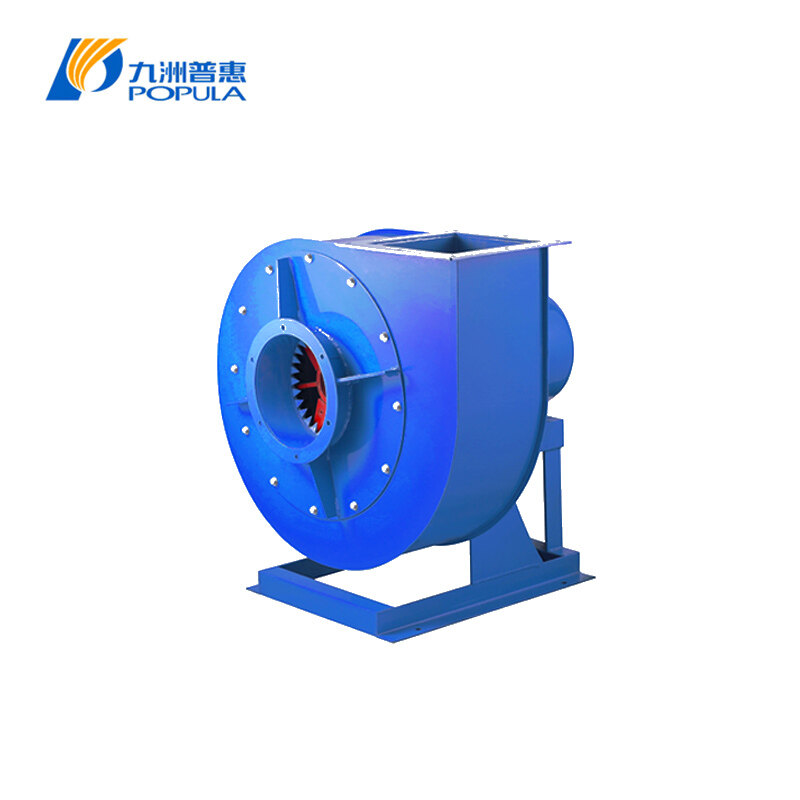

Wall-mounted industrial axial fans

Benefits of Industrial Axial Fans in Large-Scale Facilities

The implementation of industrial axial fans in large-scale facilities offers numerous advantages:

Improved Air Quality: By constantly circulating air, these fans help remove pollutants, odors, and excess moisture, creating a healthier environment.

Temperature Control: Efficient air movement aids in regulating temperature, reducing the load on HVAC systems and potentially lowering energy costs.

Enhanced Productivity: Better air quality and temperature control lead to improved working conditions, potentially boosting employee productivity and comfort.

Equipment Longevity: Proper airflow helps prevent overheating of machinery and equipment, potentially extending their operational lifespan.

Energy Efficiency: Modern industrial axial fans are designed for optimal energy efficiency, contributing to reduced operational costs and a smaller carbon footprint.

Choosing the Right Industrial Axial Fan

Selecting the appropriate industrial axial fan for a large-scale facility requires careful consideration of several factors:

Airflow Requirements: Determine the volume of air that needs to be moved based on the facility's size and specific needs.

Pressure Considerations: Assess the static pressure requirements of the system.

Environmental Factors: Consider temperature, humidity, and potential contaminants in the air.

Noise Levels: Evaluate the acceptable noise levels for the working environment.

Energy Efficiency: Look for fans with high-efficiency ratings to minimize operational costs.

Maintenance Requirements: Consider the ease of maintenance and availability of spare parts.

Installation and Maintenance Best Practices

To maximize the benefits of industrial axial fans, proper installation, and regular maintenance are essential:

Professional Installation: Ensure fans are installed by qualified professionals to guarantee optimal performance and safety.

Regular Inspections: Conduct routine checks to identify and address potential issues early.

Cleaning: Regularly clean fan blades and housing to prevent the buildup of dirt and debris, which can affect performance.

Lubrication: Keep moving parts properly lubricated to reduce wear and extend the fan's lifespan.

Vibration Monitoring: Implement vibration monitoring to detect imbalances or misalignments early.

Conclusion

Industrial axial fans are indispensable in improving airflow in large-scale facilities across various industries. Their ability to move large volumes of air efficiently contributes to better air quality, temperature control, and overall operational efficiency. By carefully selecting, properly installing, and maintaining these fans, facility managers can ensure optimal performance, energy efficiency, and a healthier working environment.

As the industrial landscape continues to evolve, the role of industrial axial fans in large-scale facilities is likely to grow, driven by advancements in fan technology and an increasing focus on energy efficiency and workplace comfort. Investing in high-quality industrial axial fans is not just a matter of compliance but a strategic decision that can lead to significant long-term benefits for any large-scale industrial operation.